As part of the formal testing phase of the project, much of the discussion in the Design Team has been around the crisis of availability of bespoke large format acrylic and perspex panels in the UK. The current affordability of rigid transparent plastics means that stores will find PPE supply at the point of sale cost prohibitive (1m square perspex bespoke free standing items currently retailing at around £200).

The reason for rigid plastic shortage is due to the 4-week manufacture hiatus, in combination with unprecedented demand. Many bespoke rigid transparent plastics are now out of stock until late August 2020, well beyond the proposed reopening phase of UK high streets, creating an impending major problem for supply of PPE for stores. Those who do have stock are prioritising essential services including the NHS and large format food retail.

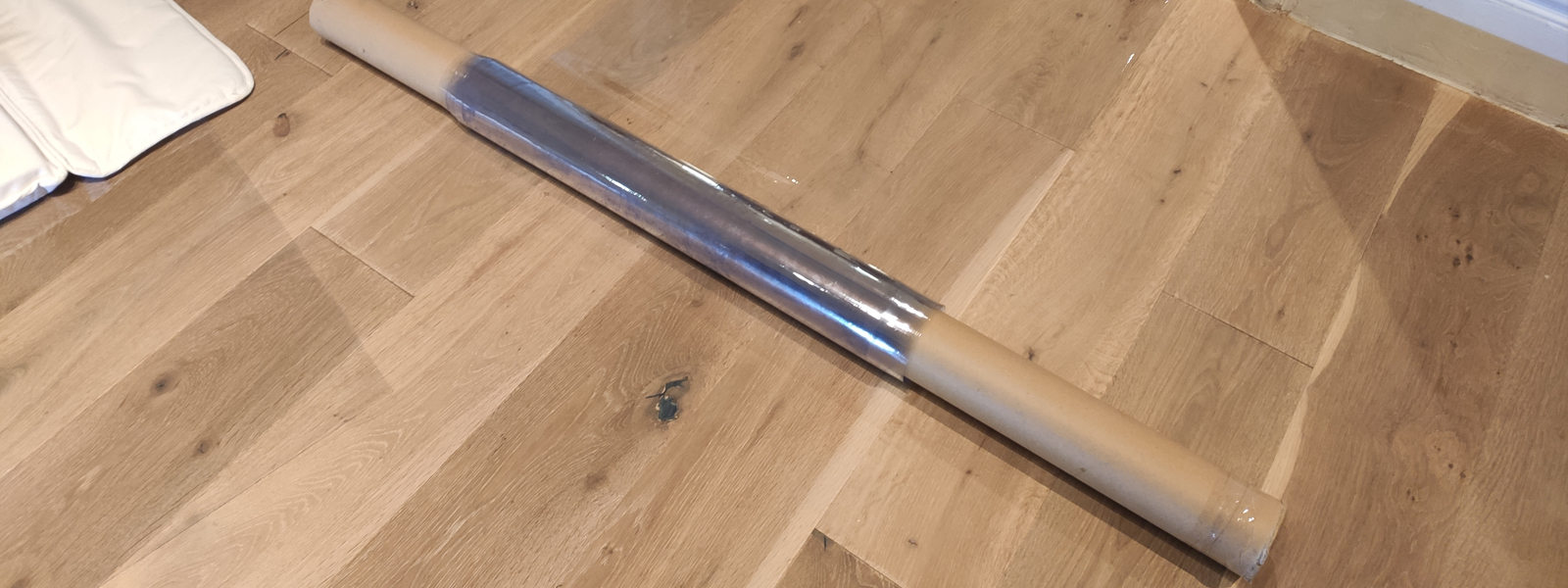

As an economic alternative, we propose a 500 micron thick plastic sheet that is used in tension much like a tent stretched across poles, and costs a fraction of rigid plastic (£3.50/m2 vs £200/m2) this is 0.018 (1.8%) the cost of rigid plastic per m2.

This has the additional advantages of being:

- easily mountable / demountable

- Entirely re-useable (if cut to the correct height, the roll can be entirely reused or returned)

- If damaged, the sheet can be wound one one side and unwound on the other to ‘move the sheet along’ on the roll

We are currently testing this for visibility, maintenance, user evaluation and durability in our pilot study in The Storey building, Lancaster.

If proven viable, this will have use for those who are unable to afford significant amounts to provide PPE shielding for social distancing.